In the rapidly evolving landscape of modern manufacturing, a revolutionary technology has emerged as a game-changer for industries worldwide: 3D printing. This innovative method of producing physical objects from digital designs has been gaining significant traction in recent years, and its benefits are multifaceted. From reduced material waste to increased design flexibility, 3D printing is poised to transform the way manufacturers approach production, opening up new possibilities for innovation and sustainability.

One of the most significant advantages of 3D printing lies in its ability to reduce material waste. Traditional manufacturing methods often involve cutting, drilling, or other processes that generate scraps, which are then discarded or disposed of. In contrast, 3D printing allows manufacturers to print objects layer by layer, using only the necessary amount of material. This approach not only minimizes waste but also reduces the environmental impact of production.

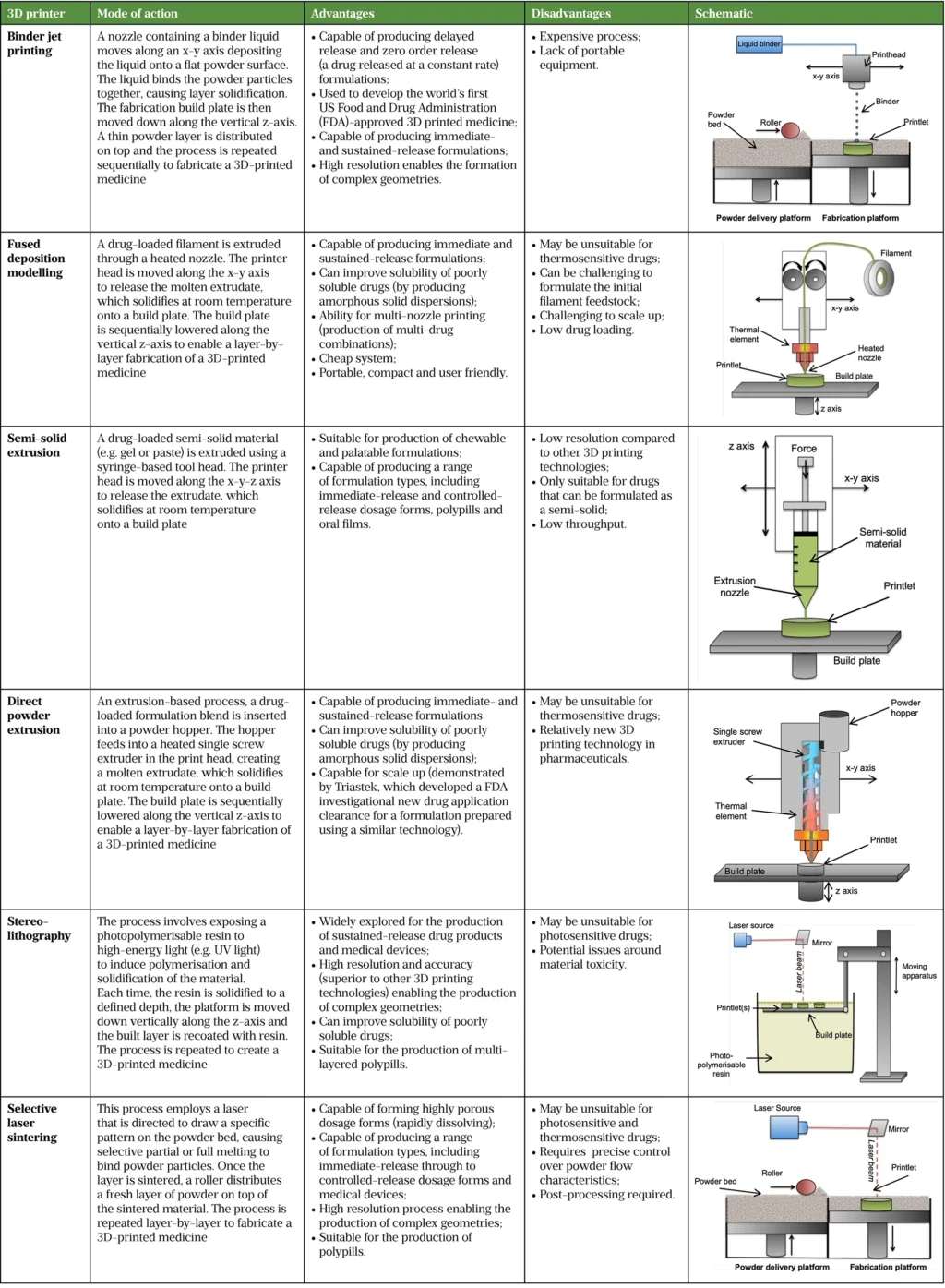

Another key benefit of 3D printing is its flexibility in design and customization. Unlike traditional manufacturing methods, which often involve mass-producing identical products, 3D printing enables manufacturers to produce complex geometries and customized designs with ease. This allows companies to create unique products that meet specific customer needs, rather than conforming to standard templates. As a result, 3D printing opens up new possibilities for product design, enabling innovators to push the boundaries of what is possible.

Furthermore, 3D printing has the potential to democratize manufacturing. With the increasing availability of affordable 3D printers and digital modeling software, individuals and small businesses can now access the technology that was previously only available to large corporations. This shift in accessibility has significant implications for entrepreneurship and innovation, enabling entrepreneurs to bring their ideas to market more quickly and efficiently.

In addition to its technical benefits, 3D printing also holds significant potential for improving supply chain efficiency. Traditional manufacturing methods often involve lengthy transportation routes, which can result in delays and increased costs. 3D printing, on the other hand, enables manufacturers to produce objects locally, reducing reliance on global supply chains and minimizing lead times.

As the technology continues to evolve, we can expect to see even more innovative applications of 3D printing in manufacturing. From rapid prototyping to production-scale printing, the possibilities are vast. By harnessing the power of 3D printing, manufacturers can unlock new levels of efficiency, innovation, and sustainability, transforming the way products are designed, produced, and delivered.

The future of manufacturing is increasingly dependent on the adoption of 3D printing technology. As companies continue to explore its potential, we can expect to see significant changes in the industry, from reduced costs to increased product customization. The benefits of 3D printing are undeniable, and as this technology continues to gain traction, it will be exciting to see how it shapes the future of manufacturing.