**The Future of Maintenance: Unlocking Predictive Maintenance’s Potential for Business Success**

In today’s fast-paced business landscape, companies are constantly seeking ways to optimize their operations, minimize downtime, and maximize productivity. One strategy that has gained significant attention in recent years is predictive maintenance – a proactive approach to equipment maintenance that uses advanced technologies to anticipate and prevent failures before they occur.

By embracing predictive maintenance, businesses can significantly reduce the frequency and duration of unplanned downtime, resulting in substantial cost savings and improved overall efficiency. According to various studies, companies that implement predictive maintenance programs can experience a 20-30% reduction in downtime, leading to increased productivity, revenue growth, and competitiveness.

**The Benefits of Predictive Maintenance**

Predictive maintenance offers numerous benefits for businesses across various industries. Some of the key advantages include:

1. **Improved uptime**: By identifying potential issues before they become major problems, predictive maintenance helps minimize downtime and keeps equipment running at optimal levels.

2. **Reduced maintenance costs**: Proactive maintenance allows companies to schedule repairs and replacements during planned periods, reducing the need for emergency fixes that can be costly and disrupt operations.

3. **Increased productivity**: With equipment running more smoothly and efficiently, businesses can increase production capacity, meet demand, and stay ahead of competitors.

4. **Enhanced safety**: Predictive maintenance helps identify potential safety hazards before they become incidents, creating a safer working environment for employees.

**The Key Players in Predictive Maintenance**

Several technologies play a crucial role in predictive maintenance, including:

1. **Artificial intelligence (AI)**: AI-powered algorithms analyze data from sensors and equipment to predict when maintenance is required.

2. **Internet of Things (IoT)**: IoT devices provide real-time insights into equipment performance, enabling proactive maintenance decisions.

3. **Machine learning**: Machine learning models help refine predictive maintenance strategies based on historical data and sensor readings.

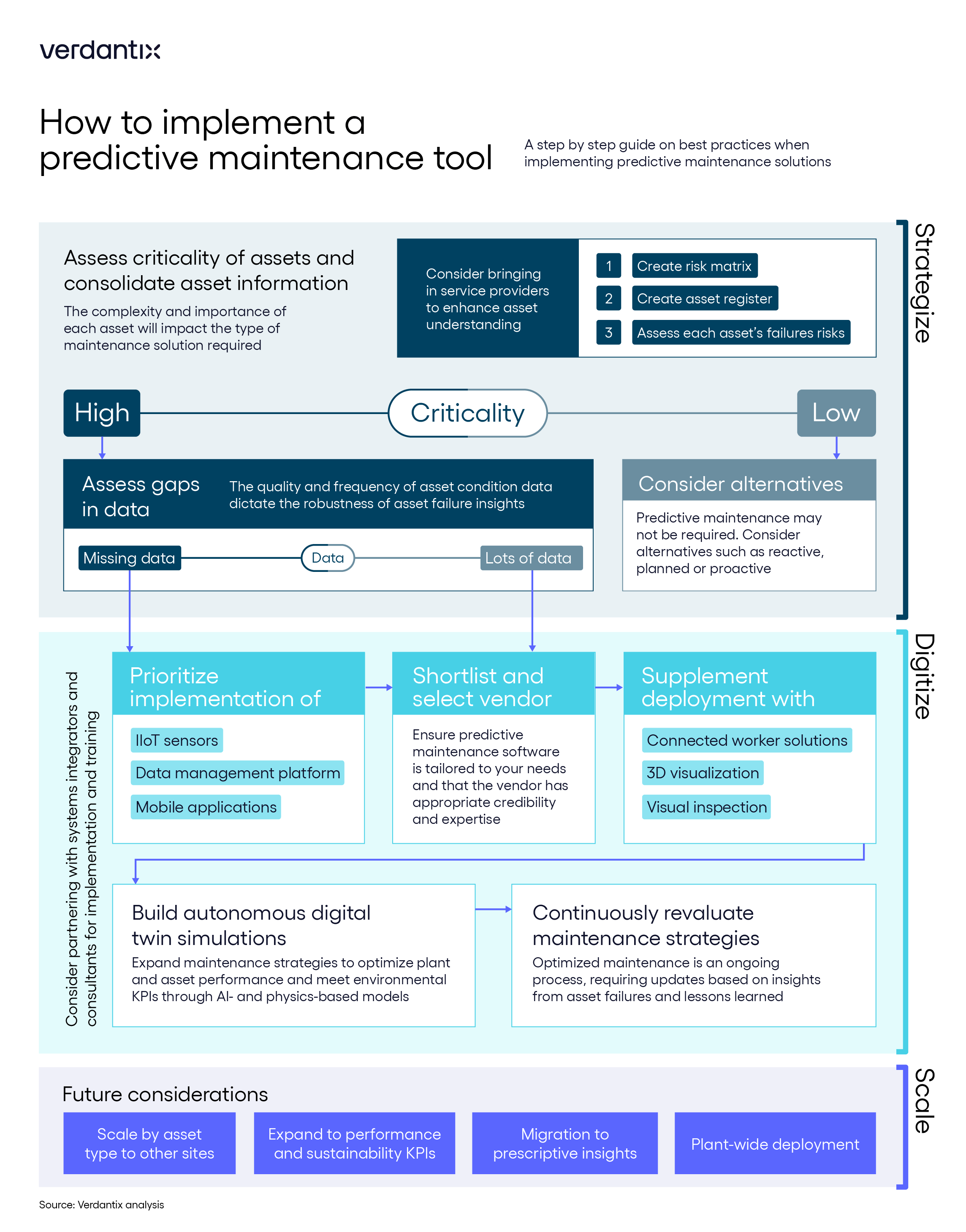

**Implementing Predictive Maintenance**

While the benefits of predictive maintenance are clear, many businesses struggle to implement such programs due to concerns about investment costs, complexity, or lack of expertise. However, with careful planning, strategic partnerships, and a phased approach, companies can overcome these challenges and reap the rewards of predictive maintenance.

By understanding the value proposition of predictive maintenance, businesses can begin to explore how this proactive approach can help them achieve their goals and stay ahead in an increasingly competitive landscape.